Half a century of trust and technology, and going forward

JEL SYSTEM was able to celebrate its 50th anniversary in 2022.

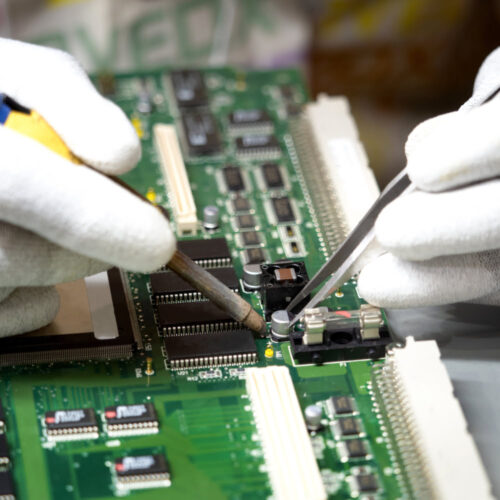

Our company has built trust with our customers based on the accumulated technology over the past half-century.

Going forward, we will continue to provide products and services that meet our customers’ needs, based on our solid expertise.